In 1992, the Danish company Christiani-Nielsen Engenheiros e Construtores was acquired. It had been operating in Brazil since 1917.

We then incorporated their expertise and technology in the construction of marine terminals, a segment in which Christiani-Nielsen was a market leader.

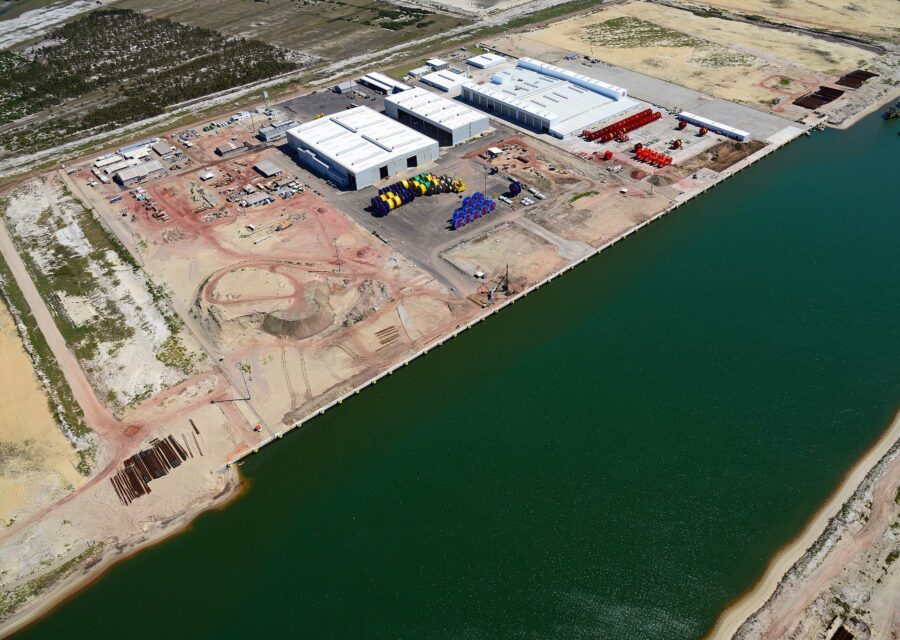

Carioca Engenharia is currently at a prominent position in marine and port construction in Brazil. We have an extensive portfolio of piers and important marine terminals on our list of achievements. This solid track record reaffirms our commitment to excellence and quality in every project we deliver.